Some may ask why does an air compressor need an air filter? Or does it really matter which air filter you choose?

It does! You only have one chance to stop contaminants – the number one enemy of rotary screw compressors – from getting into your machine. Contamination causes other problems in a compressed air system, like bearing wear, a reduced air/oil separator life, reduced lubricant life and added costs. The use of inferior filtration accelerates these issues, making the air inlet filter the most important filter in your compressor.

So, how does your air inlet filter stack up?

Conventional air filters are made of cellulose fiber elements, which often contain less media, reducing filter life and not conforming to OEM dimensions. This then leads to leaks.

When instead opting to use Sullair Optimalair air filters, you are choosing a product with a unique, proprietary filter media which utilizes nanofiber technology. Optimalair air filters enhance the compressor’s efficiency and life of the filters, resulting in high quality and cost-effective filtration that outperforms the competition.

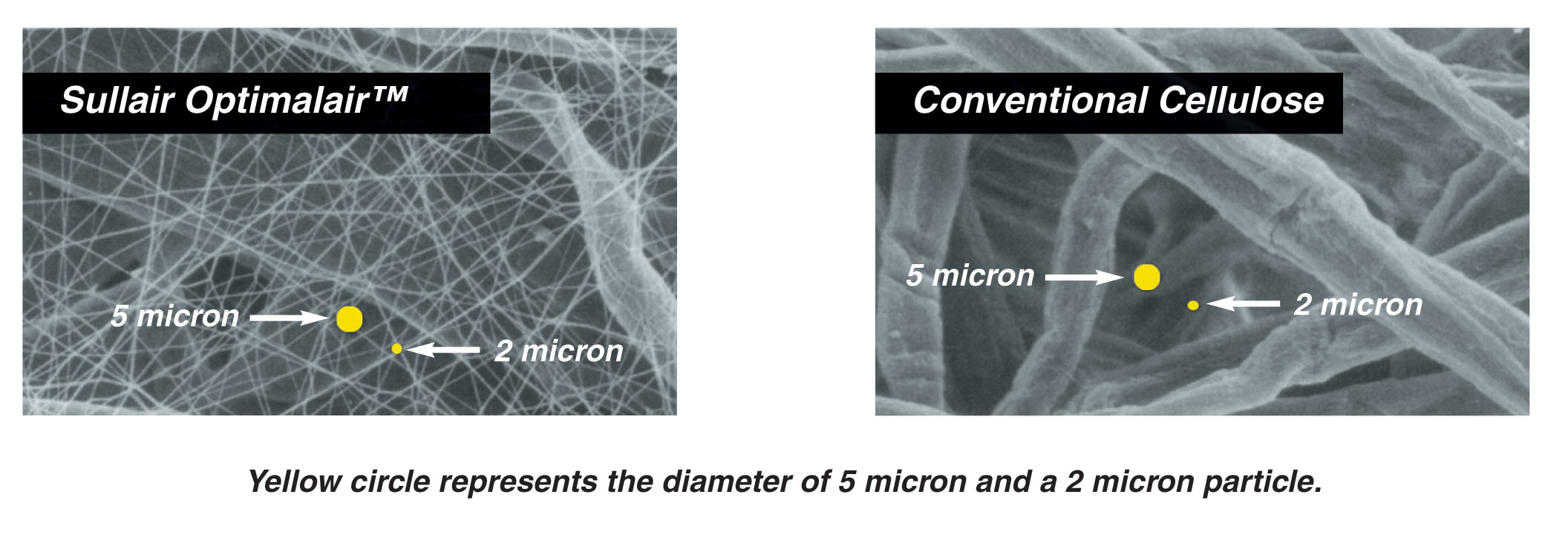

The ultra-fine filtration media in Optimalair contains two layers. In addition to the cellulose media substrate, an extremely fine layer of fibers only 0.2 to 0.3 microns in diameter, capture contaminants less than one micron in size. Rapid accumulation of particles on the filter surface builds a thin, permeable dust-stopping cake, which ensures the highest filtration efficiency by eliminating premature filtration efficiency with very low pressure drop.

Where the differences in convention cellulose media vs. Optimalair media become very apparent is in where the contaminants are captured.

Optimalair fibers have submicron diameters and small interfiber spaces between the fibers, which result in more contaminant being captured on the surface of the media and lower restriction.

Cellulose fibers are larger than Optimalair fibers and have larger interfiber spaces, causing contaminant to load in the depth of the media. Airflow is then restricted, capacity is lessened, and life is shortened.

With depth loading:

This contrasts with Optimalair filters which have higher initial efficiency than conventional media and are 99.99% efficient per ISO-5011. Optimalair filters last longer than conventional media due to superior surface loading.

Benefits of surface loading:

When selecting filter elements for your compressor, it is important to look beyond the price tag and to instead consider the long-term costs and repercussions. Choosing an extra efficiency replacement filter, like Sullair Optimalair, means fewer change intervals, which saves you on both filter costs and maintenance downtime, which no one can afford.

Use the checkboxes to select the types of cookies you want to accept, then press the “Save Settings” button. View our Privacy Policy.