When sizing an efficient system, our job as compressed air consultants is to ensure the compressors that are installed in the supply area deliver the exact amount of air required by the plant’s demand area.

Easy, isn’t it? We simply see how much air we consume on one side and choose the compressor based on that capacity and pressure. But the challenge is plant production demand varies throughout the day, or week, or year. That means compressors must adapt to those variations, and that’s where capacity controls come in.

A problem we typically encounter in the manufacturing industry is looking at only two capacity control systems: Fixed Speed Control and Variable Speed Control. This way of generalizing limits the conversation and deprives the user of finding a suitable system for installation. There are actually four capacity control systems in the industry, each with advantages and disadvantages.

Load/unload control works by means of an intake valve that determines how much air enters the compressor. The valve in these systems opens at 100% when the compressor needs to deliver air to the plant and fully closes the valve when it is no longer required, i.e., the pressure is at the proper level, the latter state is called idle work as the electric motor continues to rotate, but without compressing air. This might become a disadvantage since this system continues consuming energy from the electric motor, even though air is not being compressed.

Load/unload is the simplest control system and therefore, to generate greater energy efficiency in the compressor, it is necessary to include an air storage tank, which will function as a battery — supplying air when the system demands it.

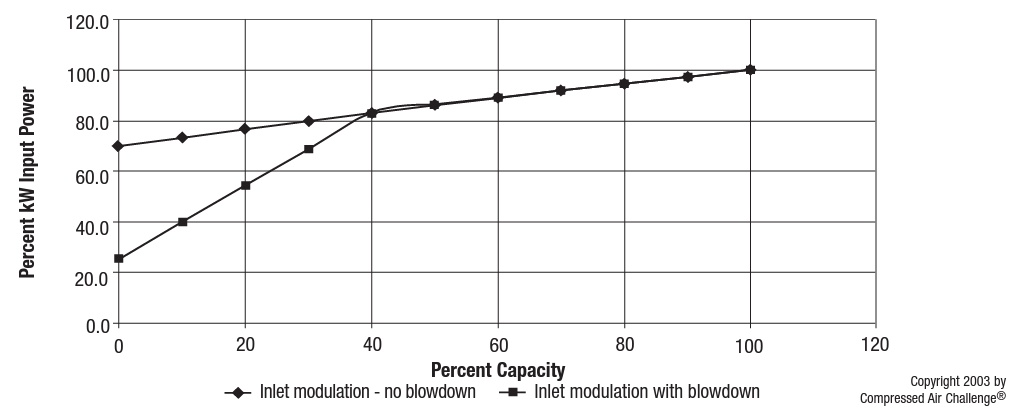

Modulation capacity control is very similar to load/unload systems. The main difference is instead of the intake valve being 100% open or closed, it “modulates” the air and allows the valve to partially open or close depending on demand. This control has several benefits; because the inlet valve modulates a little at a time, the axial loads generated in the compressor unit are lower compared to the load discharge control, which increases the life of the compressor. A disadvantage of the modulation system, however, is the gradual closure of the intake valve generates a pressure drop, which affects the energy consumption of the equipment.

Considering these two systems are so similar, the question may be what system is better suited for a given operation, modulation, or load/unload?

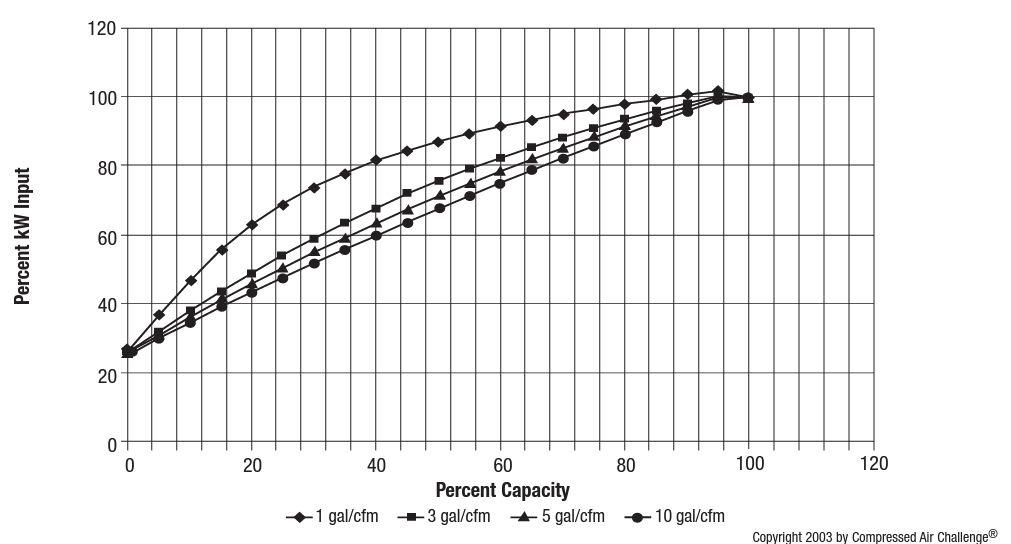

Simply put, it depends. Based on the operating curves of both systems [1], if the air consumption in the plant is very regular and the compressor works above 70% capacity all the time, then modulation is the best option in terms of energy efficiency. But if the system varies often and the compressor operates at 50% or 60% capacity load/unload can be a good option, but only if you have a well-sized storage tank. The rule in the industry for sizing storage is to have at least three gallons per cubic foot produced by the compressor. For example, if your compressor produces 500 cubic feet per minute, times three you would need a 1500 gallon buffer tank, the equivalent of 6,000 liters. Something else to strongly consider: if your air demand varies greatly, you might want to consider one of the next two capacity controls.

In Variable displacement technology, the capacity control is not performed by the intake valve, but by an additional valve that is pre-installed in the compression block. Also known as spiral valve, it opens and closes its ports gradually depending on the demand, recirculating the air that is not required to compress in order to deliver only the necessary air, generating energy savings. This system does not have the pressure drop disadvantage that modulating capacity controls have, making the variable displacement system very efficient.

Frequency variable capacity control uses an inverter or variable frequency drive to reduce the revolutions of the electric motor and the compressor block delivering only the air that is needed. This method of control is the most efficient if the compressor is working at 50% or 60% of capacity. However, if you are working at these percentages most of the time, you should consider right sizing your operations with a smaller compressor.

With variable capacity controllers and variable frequency drive controllers, the question of which system is better depends on the application. Both systems work well working under the operating ranges of 50% or 60%. However, systems that utilize a variable frequency drive are the most efficient but are also more susceptible to break down if problems of power supply or contamination in the environment exist. These are also the most expensive controls, almost 25% or 30% more expensive than the other three systems and they are the most difficult and expensive to maintain and repair. Another disadvantage is operating this control at 100% capacity will consume more energy than any of the other three controls.

Comparing the variable frequency drive and variable displacement control, the latter is not susceptible to energy or pollution issues, and maintenance costs are lower. Also, this equipment can run at 100% capacity without wasting energy. Although this capacity system is not as energy efficient at low loads as the variable frequency drive, it is the most versatile and can work in a wide operating range with high reliability and low operating costs.

The four capacity controls in the compressed air industry provide various advantages and disadvantages and require a number of questions to be analyzed and answered to correctly to size the compressor to the operating system. To lump these systems into only fixed speed and variable speed limits the analysis. In the end, the important thing to know is which capacity control will send the necessary amount of compressed air to the plant in the most efficient way possible.

If you have any doubts which capacity control your compressed air equipment uses or how to choose the best system for your current installation, contact your knowledgeable Sullair sales representative.

Use the checkboxes to select the types of cookies you want to accept, then press the “Save Settings” button. View our Privacy Policy.