While a number of compressor types exist—scroll, reciprocating, rotary screw, centrifugal, and more—all air compressors do one thing: compress air.

But how do air compressors compress air? Do the different types of compressors compress air differently and if so, how? And why does it matter, anyway?

Let’s answer the last question first.

Different uses of compressed air require the air stream to have different dimensions.[1] The most critical of these dimensions are air pressure, air flow and air quality. While all compressor types follow the same basic air compression process, some steps in that process differ for each type. Those differences can limit the practical values for some of the dimensions of the air stream they create, so the type of compressor you need depends to some degree on the use you’re putting your compressed air to.

Now that we know why the type of compressor can matter, we can go back to the first question and look at the air compression process in general. But even before we talk about the compression process, let’s take a quick look at how air compressors can get their power.

While compressed air is a source of power for air tools, instruments, and more, the compressor itself requires power. The following are the most common power sources for compressors:

The major steps in the air compression process are intake, compression, integrated storage, integrated cooling, and discharge, although not all compressors need integrated storage or cooling.

To create compressed air, you need, well, air, so the first part of the compression process is air intake. During air intake, air is drawn into the compressor through an air inlet valve.

The air inlet valve is often preceded by a filter, which protects the compressor by reducing the contaminants entering it.

The air then flows into the compression chamber where it is compressed.

We’ll look more closely at how each type of compressor does this when we cover the compressor types, but two fundamental concepts apply to all compressors.

Compressors compress air through either positive displacement or dynamic displacement (also known as non-positive displacement).

Whatever their means of compression, all compressors are either oil lubricated or oil free.

Depending on the compressor type, next the air may flow into an integral receiver tank (sometimes called a storage tank or an air tank) after being compressed.

Many uses of integrated storage are tied to the compressor type and will be covered there. However, two common reasons are shared across multiple types.

Note the difference between limited duty cycle compressors and modulating compressors.

Compressing air creates heat. While the air does not have to be cooled before leaving the compressor, most three-phase electric compressors and some diesel compressors (regardless of type) come with integrated aftercoolers to lower the air temperature before discharge.

Compressors with aftercoolers will also have water separators to remove the excess moisture that drops out of the air stream during cooling.

Finally, the air flows through the discharge valve, either directly to the point-of-use (e.g., a chipping hammer on a portable diesel compressor) or to a series of dryers and filters first (e.g., for instrument air in a manufacturing plant).

All types of air compressors follow the basic process given above, but the details can vary in important ways. Let’s look briefly at how four common types of compression work and how that affects key steps.

Scroll compressors are positive displacement, oil free compressors.

Scroll compressors use two interleaved scrolls to compress air. Depending on the design, one scroll can be fixed and the other rotate or both can rotate together. Because the scrolls never touch, no lubrication is needed.

The smooth, continuous movement of the scrolls also means that scroll compressors run quietly, have minimal vibration, and provide a pulse-free stream of air.

One notable limitation scroll compressors have is maximum air flow. While in theory a scroll compressor can scale up infinitely, the ever increasing diameter of the scrolls needed set a practical limit (at least to creating air efficiently). They have the lowest maximum flow of any of the compressors covered here.

Because they create pulse free, oil free air, scroll compressors do not require integral storage unless they use modulation.

Reciprocating compressors (sometimes called piston compressors) are positive displacement compressors and can be either oil lubricated or oil free.

Reciprocating compressors work similarly to compression chambers in car engines. On the upstroke, the piston creates a vacuum that allows air to flow into the compression chamber. On the downstroke, the air is compressed and forced out of the chamber. To achieve higher pressures and larger volumes efficiently, some designs use two stages of compression, i.e. the air compressed in the first stage is further compressed in the second stage.

Also, like a car engine, piston compressors are loud; in fact, they are typically the loudest of the compressor types covered here.

To maintain efficiency, the pistons must slide smoothly. They either need to be lubricated, which allows a small amount of oil to enter the air stream, or coated with a substance that reduces friction.

Because compression happens during only half the duty cycle, the air stream has a “pulse” when leaving the chamber rather than continuous flow and pressure.

Because their compression process creates a pulse in the air stream, reciprocating compressors always require integral storage, even when they are oil free. By providing the air from the receiver tank, instead of directly from the compression chamber, the air stream can have a continuous flow and pressure.

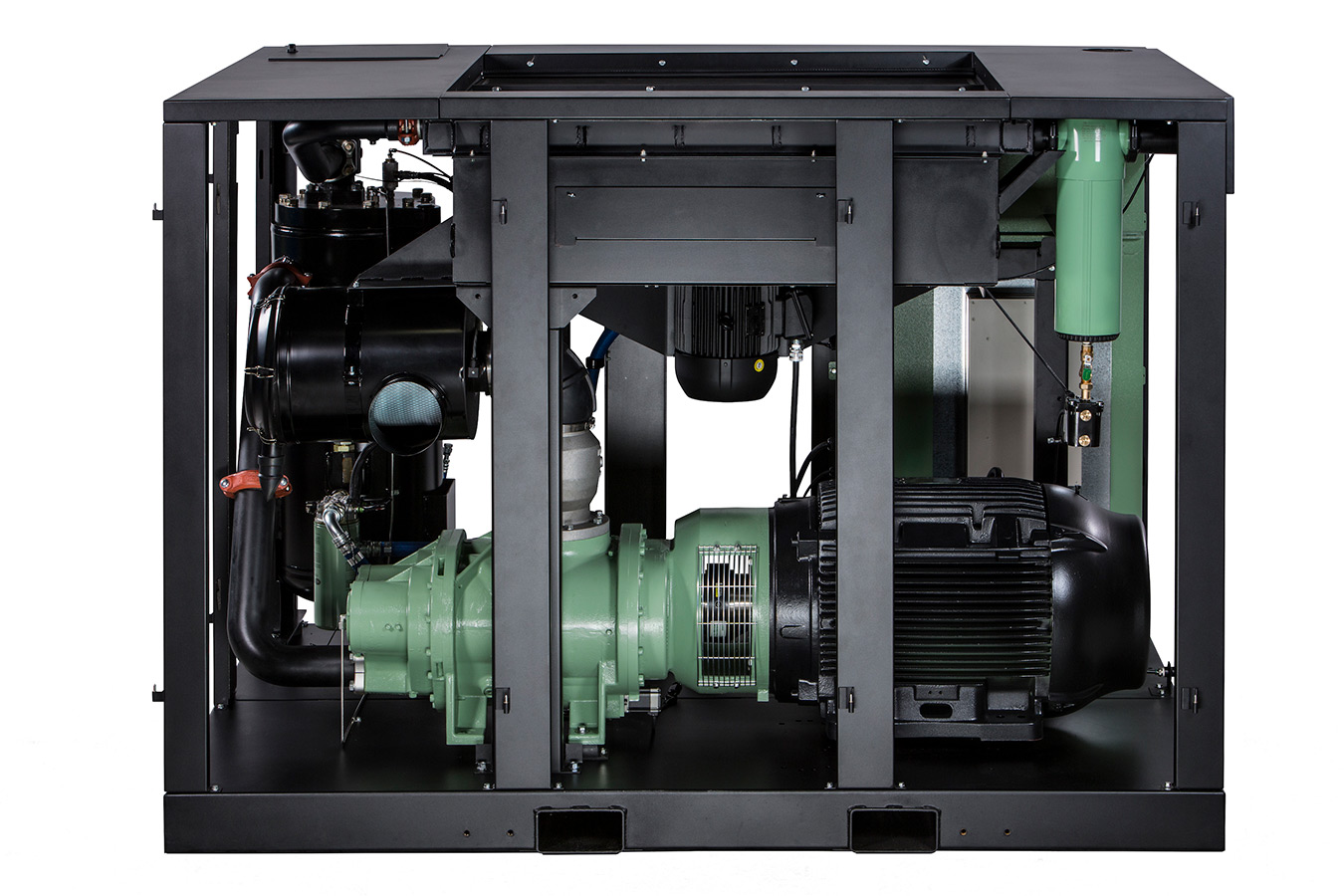

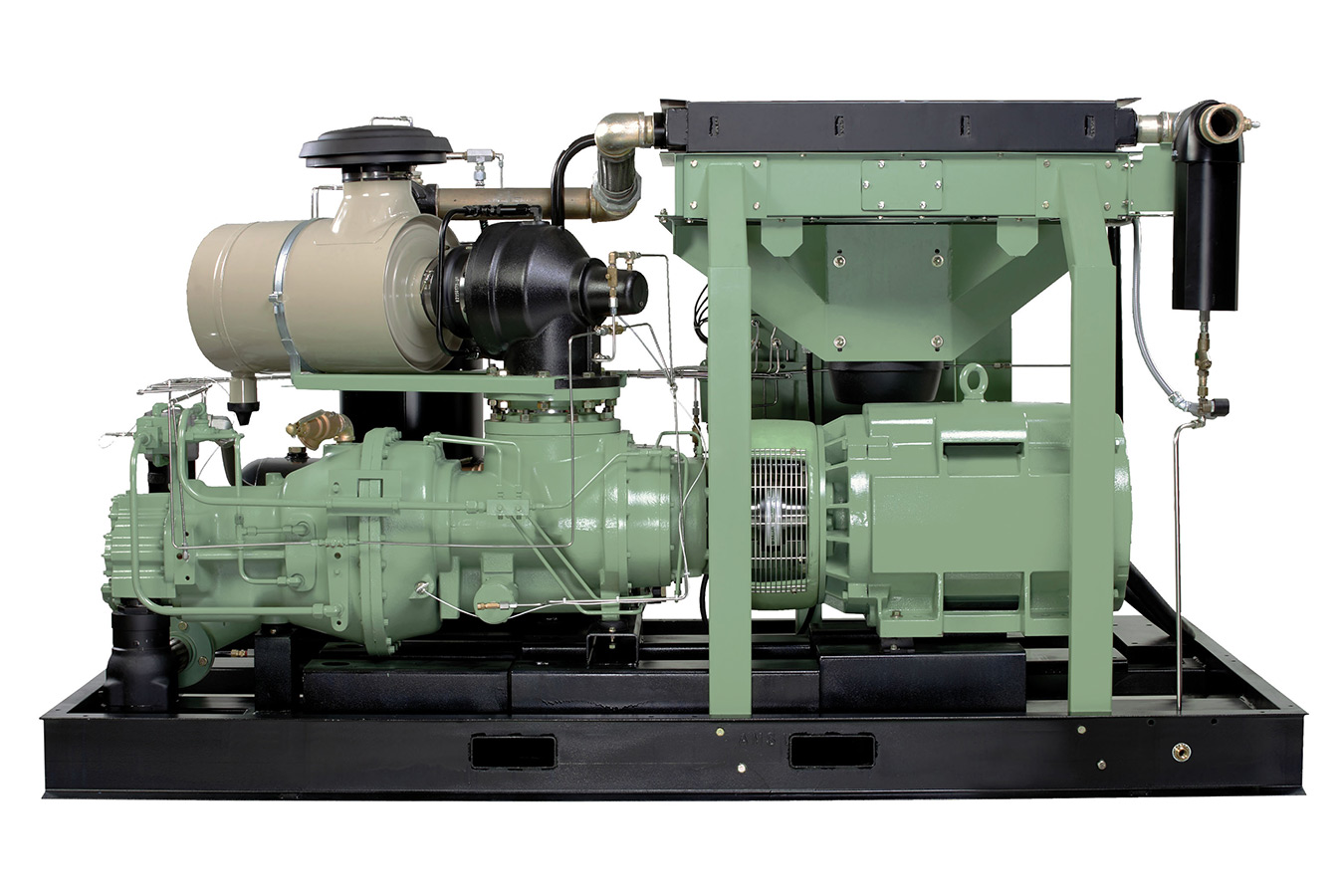

Rotary screw compressors are positive displacement compressors and can be either oil lubricated or oil free.

Rotary screw compressors use a pair of helical screws, often referred to as rotors, with lobes running the length of both. Air is forced down the length of the compressor along the lobes from a larger space into a smaller one, which compresses the air. As with reciprocal compressors, to achieve higher pressures and larger volumes efficiently, some designs use two stages of compression.

Oil lubricated screw compressors use a fluid to seal the gaps between the rotors, which also allows one rotor to drive the other, but it introduces a small amount of oil into the air stream.

Oil free screw compressors use timings with very tight tolerances between the rotor lobes instead of a fluid, so there is no oil that can enter the air stream.

Because the rotors run continuously, they produce a pulse-free stream of air. While not as quiet as scroll compressors, they are generally quieter than reciprocating ones.

Whether or not a rotary screw compressor needs integral storage depends on if it is oil lubricated or oil flooded.

Centrifugal compressors are dynamic displacement, oil free compressors.

Centrifugal compressors use an impeller rotating at high speed to initially increase the velocity of the air. Then the air is passed through a diffuser to decrease its velocity, which pressurizes the air. No lubrication is needed in the compression chamber, so no oil is added to the air stream.

Because air is created continuously as the impeller spins, the air flow and pressure are continuous, with no pulsing.

Because they create pulse free, oil free air, centrifugal compressors do not require integral storage unless they use modulation.

While knowing how compressors work can help you understand what type of compressors could work for your application, there’s more to consider: energy efficiency, maintenance costs, projected uptime, and more. Your local Sullair distributor has the experience needed to help you choose the best compressor for your needs.

Use the checkboxes to select the types of cookies you want to accept, then press the “Save Settings” button. View our Privacy Policy.