In the 30 October – 5 November 2020 edition of Engineering News & Mining Weekly, an article titled “Sullair and Hitachi Construction Machinery Zambia work together to support mining and construction in Africa” appeared in the publicat

In the oil free rotary screw air compressor world, many terms are thrown around: oil free, Class 1, “technically oil free,” Class 0, Certified Class 0 and so on.

Often referred to as the fourth utility, compressed air is one of the driving forces of modern-day life.

ITO EN’s company credo says it all. “Our mission is to put the customer first…spare no effort and earn the confidence and trust of society.”

“Turn the faucet off while you’re brushing your teeth! You’re wasting water.”

Growing up, I heard these words often.

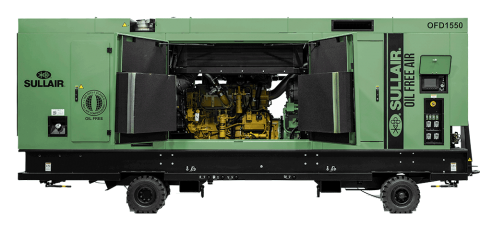

In the October 2020 issue of Compact Equipment, Navendu (Nav) Sharma, Senior Product Manager at Sullair, discusses winterizing tips for portable diesel air compressors.

Have you ever considered climbing Mount Everest or Mount Kilimanjaro and thought there is no way you would be able to survive the harsh conditions?

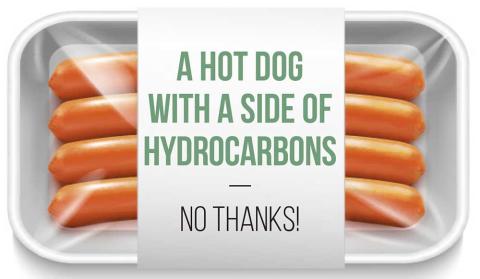

The Food & Beverage industry was shaken up in 1997 when a consumer packaging expert found mineral oil in a vacuum-sealed sausage package.

It's something no food or beverage manufacturer can operate without.

Navendu Sharma, Senior Product Manager with Sullair, provided commentary in the September 2020 issue of Compact Equipment.