Rotors

Precision ground asymmetric profile delivers an optimal combination of capacity and power. Rotor speed range: 15 m/s to 50 m/s on male rotor tip.

Discharge

Several built-in volume ratios offer a range of pressure ratios meeting specific application requirements.

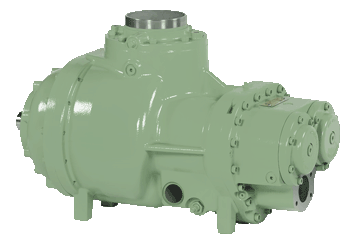

Casing

Heavy duty, double-wall cast iron casing provides for structural rigidity, pressure integrity, and low noise.

Drive Adaptor

Available drive adaptors (Flywheel adaptors or base-mounted) offer a convenient means to match up the gas end with the drive unit.

Shaft

Steel input shaft can be easily adapted/coupled to the driver with a variety of methods - keyed fit, mechanical locking or shrink-fit coupling hub. Drivers used include: natural gas and diesel engines, 1800 rpm, 3600 rpm motors and variable speed drives.

Mechanical Shaft Seals

Constructed from high-temperature metallized carbon with tungsten facing and Viton elastomers, seals provide a superior seal and the highest dependability – meeting the critical standards for process gas applications. These seals are flange mounted for easy maintenance and oil-cooled for long life.

Bearings

Anti-friction bears are manufactured from all-steel (no plastic or “yellow metal” cages) construction for superior durability. Tapered roller bearings absorb thrust and radial loads; straight while roller bearings handle opposite end radial loads both contributing to the optimal performance of the rotors, even in the harshest conditions.

Gears

AGMA Class 11 Gears allow for a variety of internal gear ratios contributing to design optimization and operation economy.

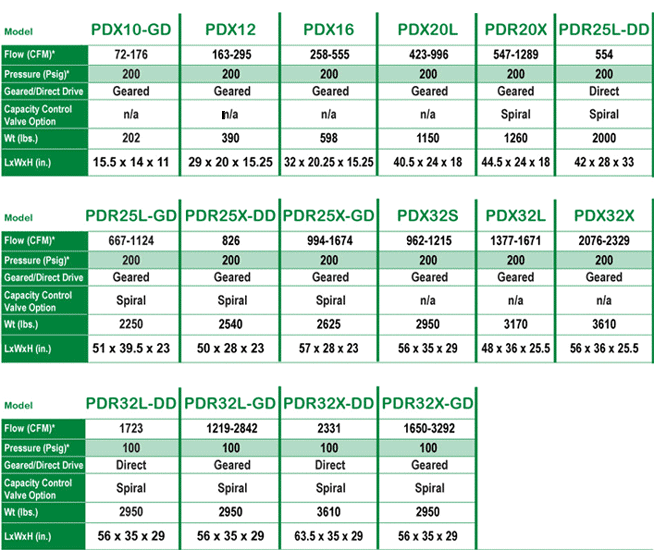

Capacity Controls Options

Capacity controls are an option offered on several models via slide valves (Refrigeration Series) or spiral valves (Process Gas low pressure and high pressure gas ends). These controls allow gases that have been only slightly compressed to bypass back into the suction head. Capacity can be manually adjusted or automatically controlled based on pressure signal down to as low as 10% of full load working capacity (slide value) or 50% of capacity (spiral valve).

Factory Tested

All Process Gas/Refrigeration Gas ends are hydro tested to 1.5 times maximum allowable working pressure and air tested to ensure highest quality/power and capacity performance prior to being shipped.

Warranty

Sullair Process Gas /Refrigeration Gas ends are warranted for a full year against defects in materials and workmanship.